WE STAND FOR THE HIGHEST PRODUCT QUALITY IN TECHNICAL RUBBER GOODS

“MADE IN GERMANY” ALONG THE ENTIRE PRODUCTION PROCESS

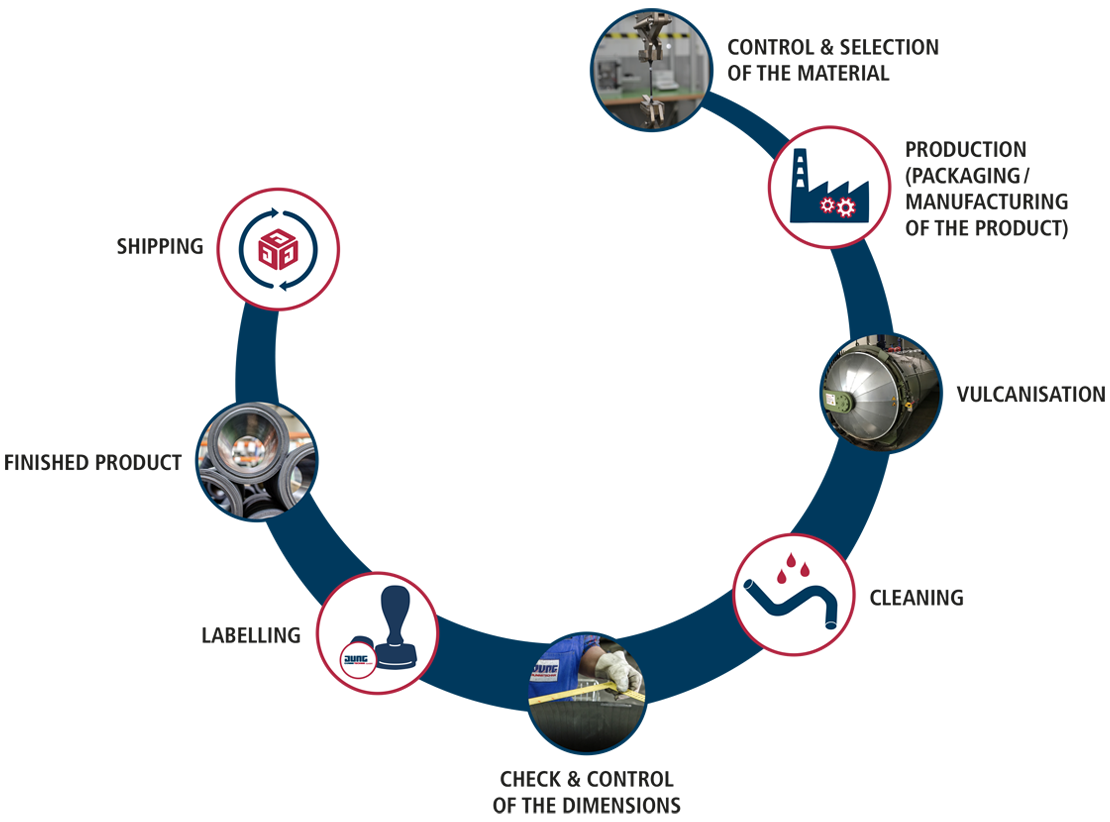

We manufacture our technical rubber goods completely “made in Germany” and stand for the best quality. We produce our technical rubber goods exclusively at our site in Einhausen and can therefore accompany the creation of our rubber components and moulded parts through to the finished product at every stage and ensure the enforcement of high quality standards. Proven regional partners cooperate with us in the production of tools for applications such as special parts or moulded hoses. We are strong in transforming individual customer enquiries and requirements into a solution after qualified consultation. From individual parts to small series, we can serve all customer requirements. On request, we design our products to national and international standards.

CONTROL AND MATERIAL SELECTION FOR TECHNICAL RUBBER GOODS:

- We undergo regular external controls to ensure consistent quality requirements.

- The material selection is made in close consultation with our proven compounders.

- A strict incoming goods inspection takes place before processing.

- Technical rubber goods are usually counter-checked and released by the customer with an initial sample test report (acceptance test certificate 3.1 DIN EN 10204) for correct production and implementation.

PRODUCTION OF TECHNICAL RUBBER GOODS:

- For hoses, elbows and moulded parts, we take care of the application-specific, individual implementation according to customer requirements and drawings.

- We ensure process reliability. Environmental influences are precisely controlled to enable consistent production conditions.

- The vulcanisation process of hoses and elbows takes place in a boiler that has been adapted to us. Moulded parts are vulcanised separately by a pressure and pressing process.

- All technical rubber goods are cleaned by adapted processes.

TESTING AND CHECKING THE MASS OF TECHNICAL RUBBER GOODS

- Depending on the requirements, an outgoing goods inspection of up to 100 percent is carried out. Properties such as length, diameter, weight, optical integrity, tightness and wall thickness are checked.

- Our in-house testing laboratories offer the possibility to test all mechanical properties such as pressure and vacuum, conductivity, tensile and tear propagation and abrasion resistance on site upon request.

LABELLING AND PACKAGING OF TECHNICAL RUBBER GOODS:

- The marking of hoses, elbows, moulded articles and other components is individually possible.

- Each product is inspected after completion and cut and packed according to specifications so that it can then be handed over to the respective shipping companies.

- For example, FDA conformity and electrical conductivity can be confirmed with a certificate on request. For technical rubber goods we can issue a works certificate according to DIN EN 10204 – 2.1, 2.2 and 3.1.

- Our technical rubber goods are in demand all over the world and find their way to their respective destinations by road, water or air. If necessary, export processing is carried out in cooperation with our customers by our Order Processing department.

We are also happy to issue factory certificates on request:

- Fire protection

- Pressure test

- Initial sample inspection report

- Conductivity

- Food certificate

- Factory certification according to 2.1; 2.2, 3.1