HIGHEST QUALITY LEVEL IN SPECIAL GLOVES AND PROTECTIVE GLOVES FOR GLOVEBOX, INSULATOR AND RABS APPLICATIONS AS WELL AS OCCUPATIONAL HEALTH AND SAFETY

STATE-OF-THE-ART MANUFACTURING PROCESSES AND 100% CONTROLS ENSURE QUALITY

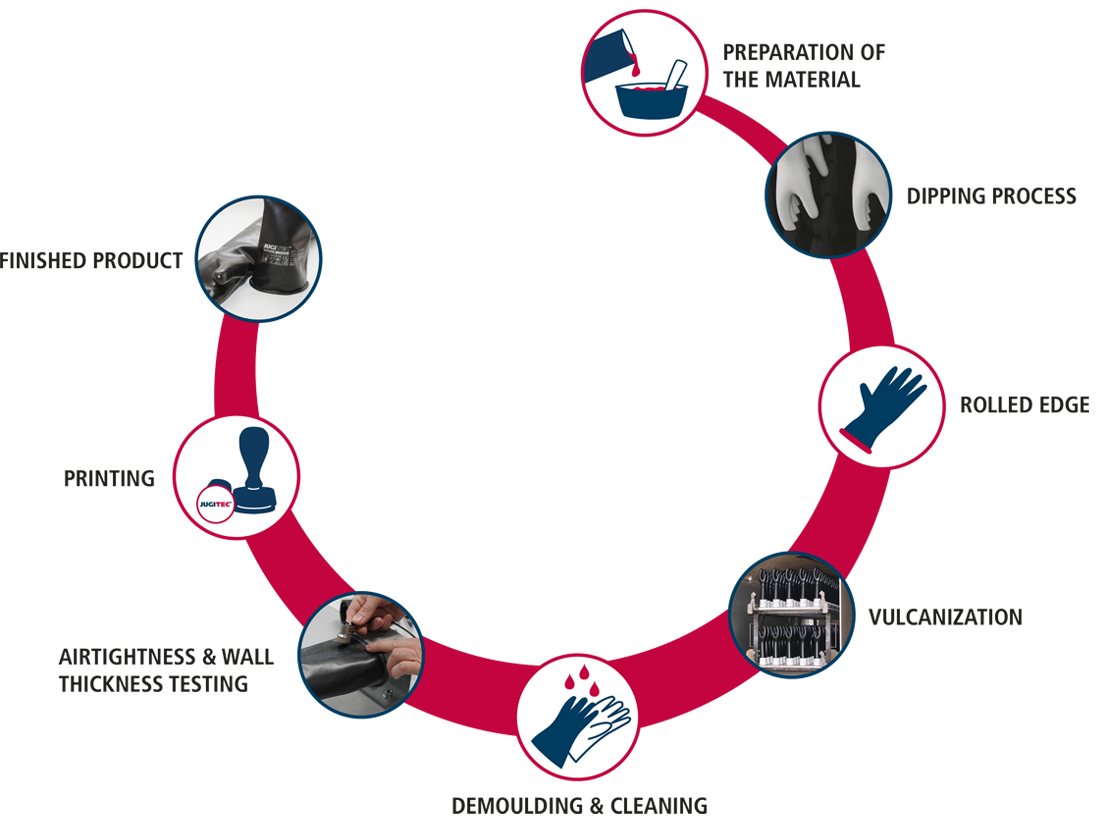

Our type-examination-tested glovebox gloves and our special protective gloves for category III occupational safety (chemical occupational safety as well as insulating electrician's gloves) are manufactured using the dipping process and convince with the highest quality. The dipping processes are continuously monitored – taking into account all relevant parameters – and are kept at the most modern level to meet all requirements. In this way, we can ensure consistently high quality for every single new batch. State-of-the-art production processes and careful handling of the resources we use ensure that our products are manufactured ecologically and sustainably.

We also manufacture our special gloves and protective gloves completely “made in Germany” and thus ensure consistently high quality in this segment as well. Our production is carried out exclusively at our two locations in Germany (Einhausen and Warstein) – allowing us to control and monitor production at every stage. We are certified according to DIN ISO 9001:2015 and ISO 14001:2015 and ensure sustainability as well as the best possible process flows. In order to be able to offer high-quality and safe protective gloves made of rubber (caoutchouc, elastomer polymers), we have committed ourselves to consistent production monitoring – all this taking due account of customer-specific standards and compliance with the highly demanding GMP guidelines.

CONTROL AND MATERIAL SELECTION FOR GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS PROTECTIVE WORK GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN GLOVES):

- Our protective glove products are externally controlled by the highest safety standards for personal protective equipment (PPE). Module D monitoring of all PPE articles and type examinations at prescribed intervals are carried out by externally notified bodies.

- Regular external controls prove the consistent quality requirement.

- The material selection, the consistent quality and adherence to the recipes of the respective rubber compound are realised in close consultation with our proven compounders.

- Before the rubber is processed, a strict incoming goods inspection takes place.

PRODUCTION OF GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS INDUSTRIAL SAFETY GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN GLOVES):

- We ensure process reliability. Environmental influences are closely controlled to enable consistent production conditions of our protective work gloves.

- Our special gloves undergo vulcanisation in a cauldron adapted to the specific requirements.

- All gloves are cleaned by adapted processes such as tumbling, washing or similar.

TESTING AND CHECKING THE MASS OF GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS INDUSTRIAL SAFETY GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN'S GLOVES)

- We take care of air tightness and wall thickness tests of our finished special gloves, perform a dimensional check of the length, material thickness (five measuring points) and the rolling rim diameter of the rubber glove.

- We carry out an airtightness test in accordance with test method B/DIN EN 421 on the industrial safety gloves. The quality system for Jugitec products allows complete traceability of all material, process and test parameters – for each individual glove and for each user. Test certificates and information sheets on safe handling are enclosed with every delivery.

- The outgoing goods inspection is carried out up to 100 percent, depending on the requirements: The visual inspection is carried out for each individual glove.

- Additional properties such as length, diameter, weight, tightness and wall thickness are checked according to AQL 1.5. In the event of a discrepancy, a 100 per cent check is also carried out.

- Our in-house testing laboratories offer the possibility to test all mechanical properties of the special gloves such as permeation behaviour, pressure and vacuum testing, conductivity, tensile and tear propagation testing, abrasion resistance and puncture resistance on site upon request.

- All the special gloves we make are carefully scrutinised before they are sold. Here, all process parameters are documented and checked in detail by our final inspection. These tests are carried out on the basis of manufacturer's solder, WPZ (factory test certificate), as well as rheological and mechanical material tests. Material and permeation tests are carried out in the company's own test laboratory.

LABELLING, PACKAGING AND SHIPPING OF GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS INDUSTRIAL SAFETY GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN GLOVES):

- The rubber protective gloves are labelled with the type designation, production date and batch number.

- PPE items are labelled with all relevant information such as date of manufacture, batch number and material type or individually on customer request.

- Each protective glove is inspected on completion and cut to specification and packaged in a suitable light protected polybag.

- On request, FDA conformity and electrical conductivity of the protective work glove manufactured by us can be confirmed with a certificate.

- We can issue a Certificate of Conformity (CoC) for glovebox, insulator and RABS gloves.

- Depending on the delivery quantity, the protective gloves are packed according to our own specifications or also at the customer's request and handed over to the selected forwarding agent.

- Our glovebox, insulator and RABS gloves as well as industrial safety gloves are in demand worldwide and make their way to their respective destinations by road, water or air. Export processing is carried out in cooperation with our customers by our Order Processing department.

We are also happy to issue factory certificates on request:

- Certificate of Conformity

- Food certificates such as FDA standard

- Various customer-specific verifications

- CE conformity

TESTING AND LABELLING

The quality system of our Jugitec products allows complete traceability of all material, process and test parameters – for every glove and every user. Test certificates and information sheets on safe handling are enclosed with every delivery.

Schritt

Cleaning the gloves

Schritt

100% visual inspection of the surface

Schritt

Dimensional check of length, material thickness (5 measuring points) and rolling edge diameter

Schritt

Air tightness test according to test method B in accordance with DIN EN 421

Schritt

Labelling with type designation, production date and batch number

Schritt

Packing in suitable light-protected polybag